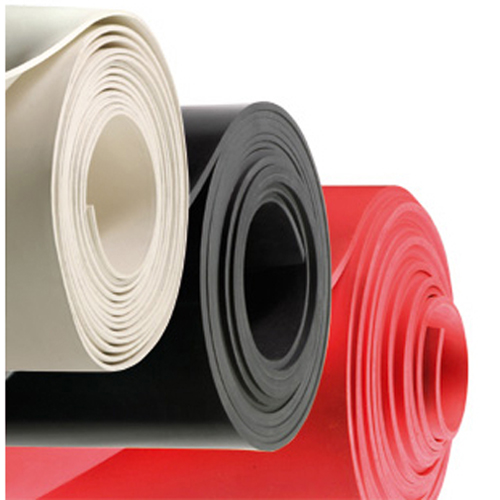

Hypalon Rubber Sheet

Hypalon Rubber Sheets are very resistant to oxygen/ozone, and have good heat resistance with an “EE” by ASTM D2000 being obtainable. They also show excellent resistant to corrosive chemicals.Temperature:Compunds can be formulated for excellent abrasion resistant and for brittle temperatures as low a......Send Inquiry

Product Description

Hypalon Rubber Sheets are very resistant to oxygen/ozone, and have good heat resistance with an “EE” by ASTM D2000 being obtainable. They also show excellent resistant to corrosive chemicals.

Temperature:

Compunds can be formulated for excellent abrasion resistant and for brittle temperatures as low as – 60 oC (- 76 oF).

Application:

Properly compounded products show excellent weathering resistance. Hypalon rubber has excellent electrical properties. They can also be compounded for good flame resistance.

Specification:

|

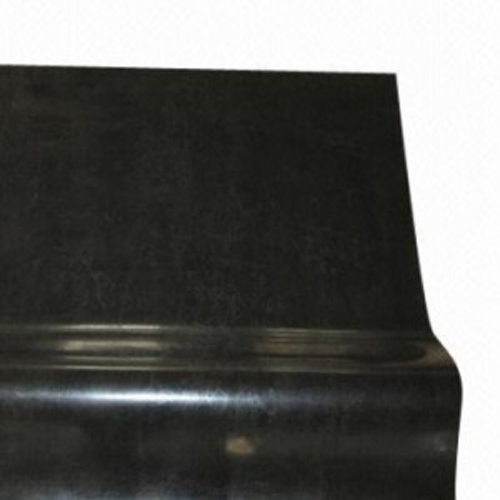

HYPALON RUBBER SHEET: BLACK |

|||||||

|

Model |

Specific Gravity |

Hardness (±5) |

Tensile Strength |

Elongation at break |

Tear Strength |

Compression Set at 70°C for 22 hrs |

Working Temp. |

|

g / cm3 |

Shore A |

(min) kg / cm2 |

(min) % |

kg / cm |

% |

°C Range |

|

|

HR1401 |

1.40 |

65 |

100 |

350 |

25 |

40 |

-35/130 |

|

HR1301 |

1.30 |

50 |

80 |

300 |

15 |

40 |

-35/110 |

|

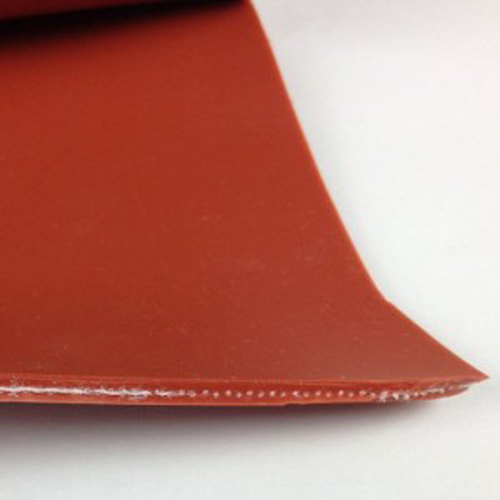

HYPALON RUBBER SHEET DIFFERENT COLORS |

|||||||

|

Model |

Specific Gravity |

Hardness (±5) |

Tensile Strength |

Elongation at break |

Tear Strength |

Compression Set at 70°C for 22 hrs |

Working Temp. |

|

g / cm3 |

Shore A |

(min) kg / cm2 |

(min) % |

kg / cm |

% |

°C Range |

|

|

HR1451 |

1.45 |

70 |

70 |

250 |

25 |

40 |

-30/130 |

|

HR1551 |

1.55 |

60 |

60 |

250 |

20 |

40 |

-30/130 |

|

Standard Length |

10 Mtr |

10,000mm |

33ft |

11 yard |

|

Standard Width |

1.2 / 1.4 / 1.5 mtr |

1200 / 1400 / 1500mm |

4 / 4.6 / 4.92ft |

1.33 / 1.53 / 1.64 yard |

|

Standard Thickness |

1 – 50 mm |

1/32″ – 2″ |

||

|

Colors |

red/grey/blue/green |

|||